Power Management Systems

RPM believes the greenest energy is the energy that isn't consumed, and that intelligent management of available energy is paramount for the future. Peak shaving, power factor correction, and load leveling are the areas that RPM will pursue in a variety of industries.

The use of energy storage, efficiently capturing regenerative energy, and improving power factor, enables us to design highly efficient machines along with retrofitting existing plants.

Power Management Options

RPM believes that two methods of power management can be adopted to greatly reduce the demand on local utilities:

-

Decentralized

- Peak shaving at the machine center utilizing energy storage in conjunction with the DC bus of a VFD or servo drive.

-

Centralized

- At the utility connection to the plant, using energy storage systems that can manage peak shaving and power factor improvement.

Enabling Technology

-

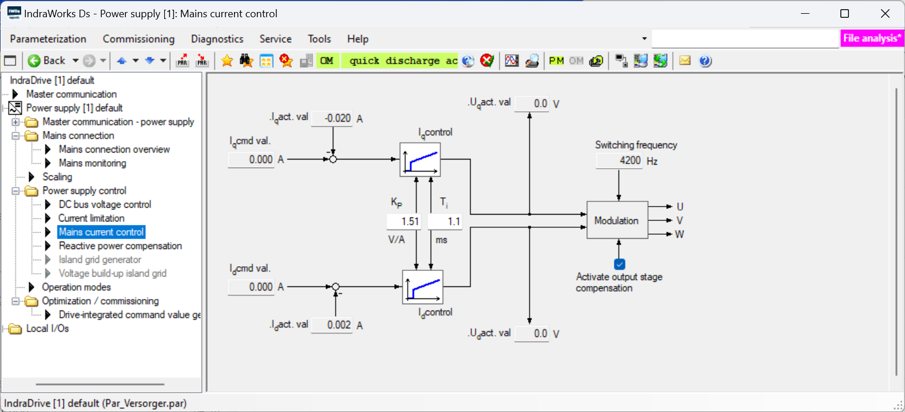

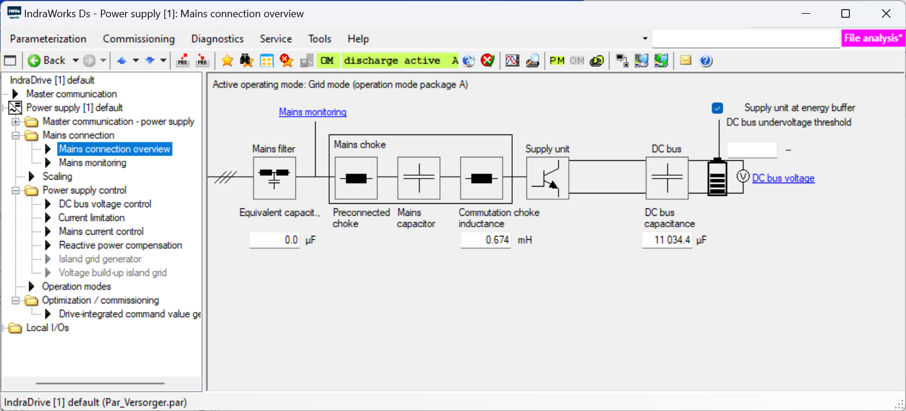

Bosch ML Drive

- Common hardware for active front end or inverter

- Proven - on the market for over ten years

- Up to 540 kW per drive

- Stackable for up to 4 MW total power

- Mains current control mode that can independently control reactive and active current

-

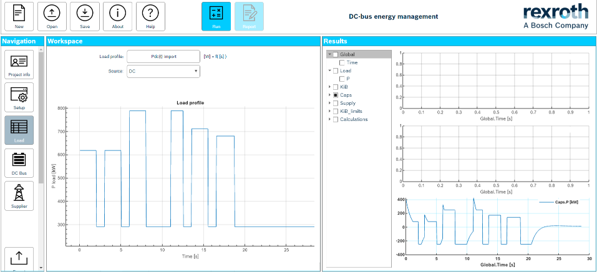

DC Bus Energy Storage Options

- Super capacitor

- Super battery

- Li-ion battery

- Kinetic buffering

Design Process

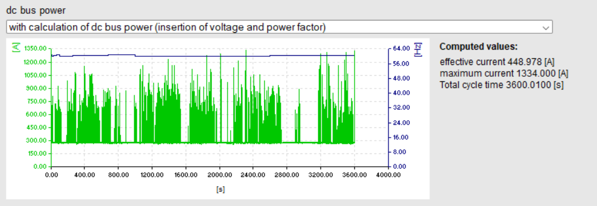

- To accurately dimension a power management system, a thorough understanding of the plant's processes is required.

- RPM can collect live data from existing systems to design and accurately determine what level of "peak shaving" is achievable.

- Using our supplier's proprietary software and modeling packages, along with measured field data, we generate a system model.

- The model provides design parameters for the energy storage medium, drive power supplies, and inverters.

Load cycle of 800 HP motor

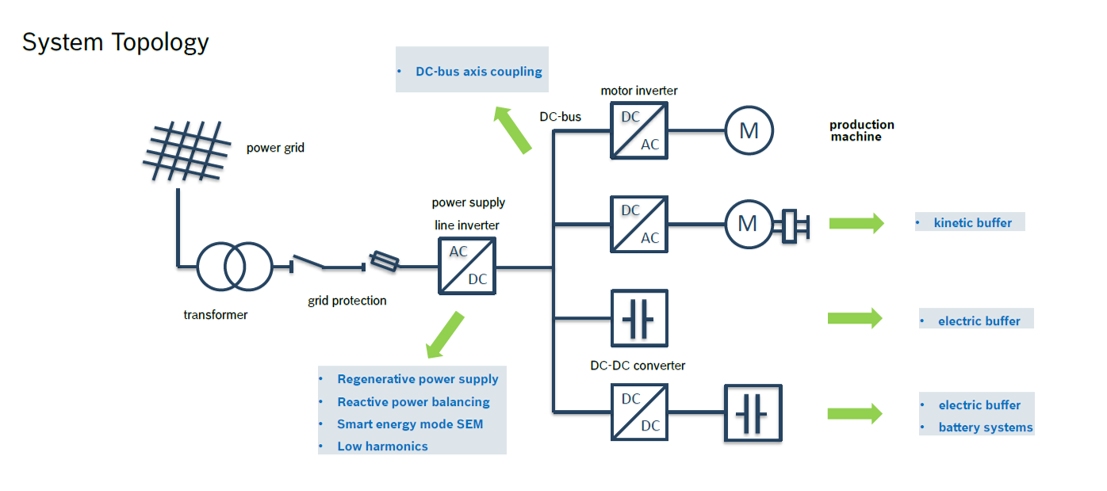

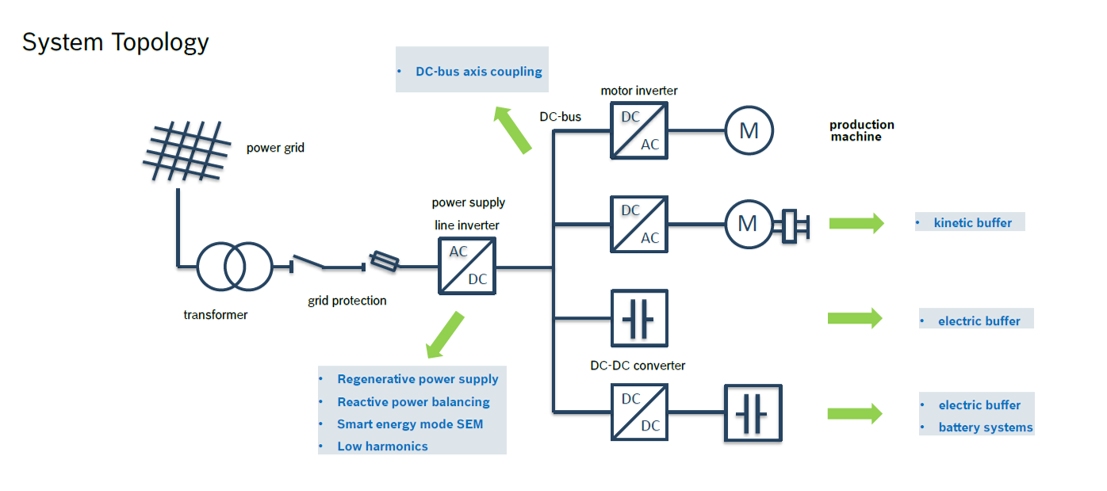

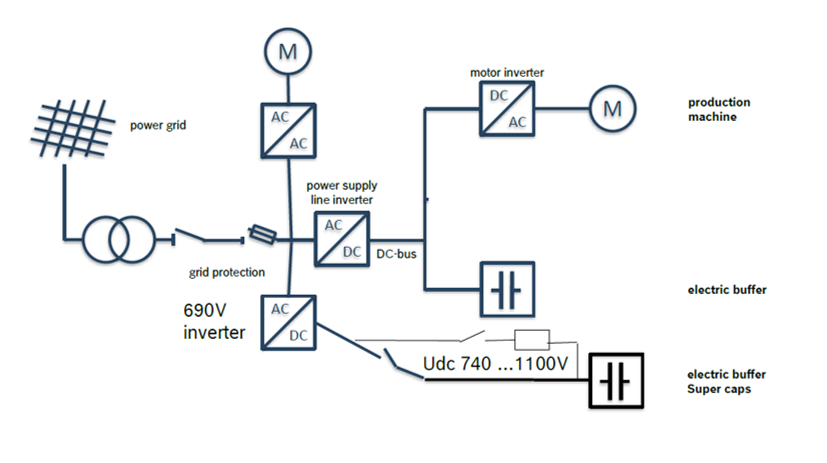

Decentralized Power Management

- Peak shaving utilizing DC bus energy storage in conjunction with VFDs or servo drives

-

Active front end

- Regenerative power supply

- Near unity power factor

- Multi-inverter load sharing via common DC bus

-

Energy storage options:

- Kinetic buffering

- Super capacitors

- Battery

- Compliant with IEEE 519 Total Harmonic Distortion Requirements (Typically <2.5% THD)

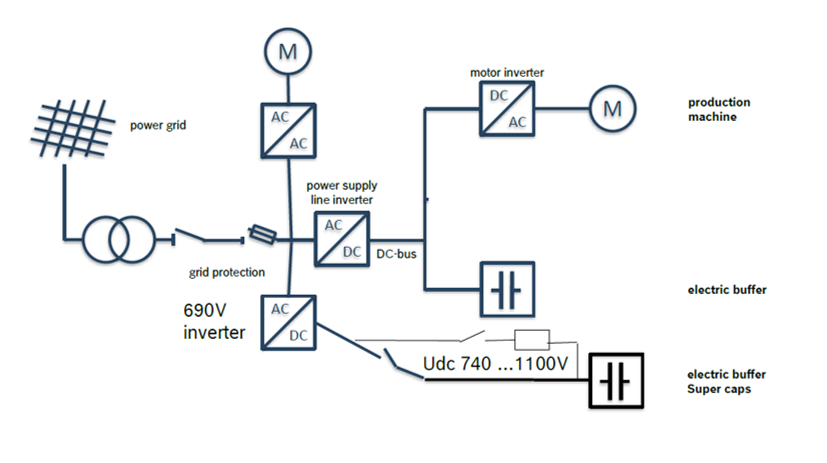

Centralized Power Management

- Non-intrusive to the plant's operation

- Connection point on the AC bus of the plant

- Modular and scalable to suit the customer's needs

- Can be implemented with decentralized power management systems

- Remote diagnostic capacity, service, and data acquisition

- Available range of voltages: 460-600 VAC

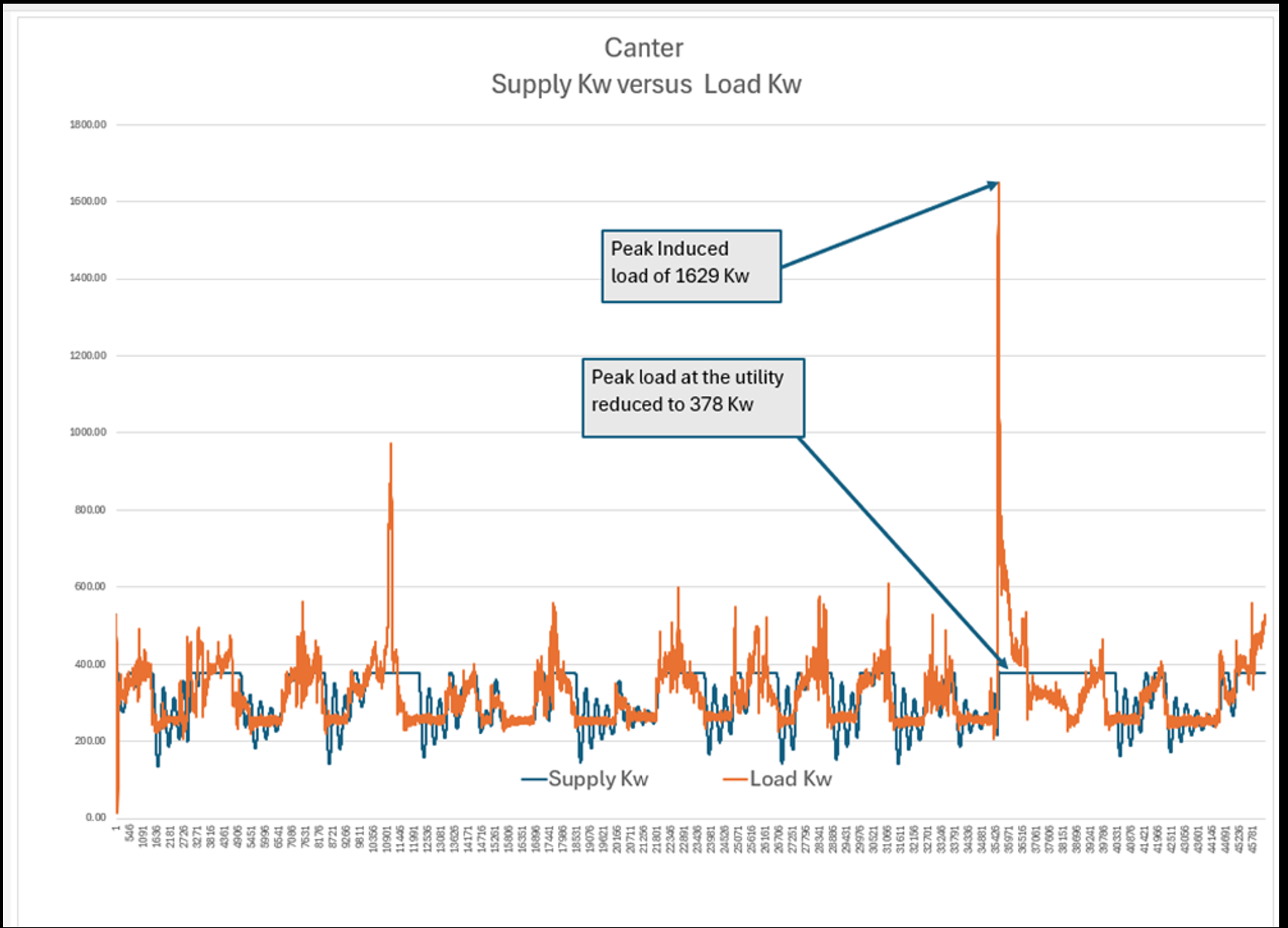

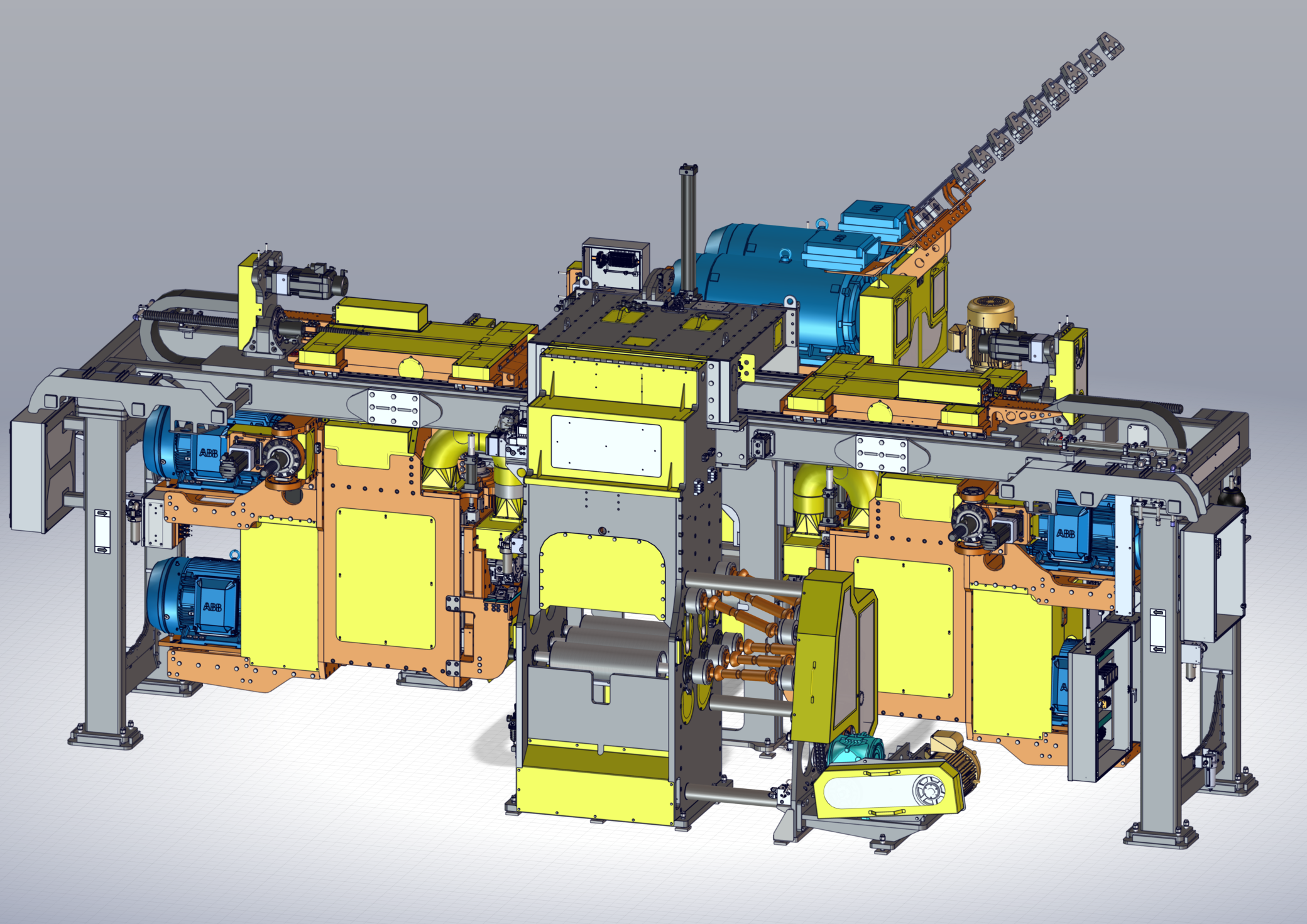

Example Application - Decentralized Power Management

- Completed in 2021

-

System Topology

- (4) 300HP induction motors on chipping heads

- (1) 540 kW regenerative power supply

- (18) 102V 88F supercapacitors (2 parallel strings of 9)

- (4) 430 kW inverters connected to a common DC bus

- System protection, filters, and control

Results

- 41% decrease in peak demand

- More peak power available for motors on the same machine PDC

- Improved machine performance

- Variable speed on large motors

- Improved chip quality

- Increased feed speeds